Arc Flash Compliance and Training Solutions

Get a Free Estimate Today

** We do NOT send any marketing texts or emails.

EAP is Trusted by

ExxonMobile

Memorial Herman Hospitals

CBRE

JLL

And Many More

Get Compliant with an EAP Arc Flash Study

Ensure Reliability Safety with the Most Experienced in the Business

40+ Years of Experience

FREE Arc Flash PPE Labels

FREE NFPA 70E safety training

FREE System Hazard Detection

Guaranteed NEC Compliance

Proven Track Record of Safety

Trusted by:

ExxonMobile

Memorial Herman Hospitals

MD Anderson Hospitals

CBRE

JLL

And Many More

Get a Same-Day Free Estimate

** We do NOT send any marketing texts or emails.

Arc Flash Study Info

What is an Arc Flash Study?

An arc flash study, in simple terms, is like a safety assessment for electrical systems. Imagine your home's electrical panel but on a much larger scale, like in a high rise building, a hospital or an industrial facility. These studies evaluate the risks of sudden, intense electrical explosions called arc flashes that can happen when something goes wrong in these systems. Electrical Engineers analyze the setup, equipment, and procedures to figure out how to minimize the chances of these dangerous flashes occurring. This helps protect people working with or near electricity by recommending safety measures like wearing protective gear and following specific safety protocols to prevent injuries and damage.

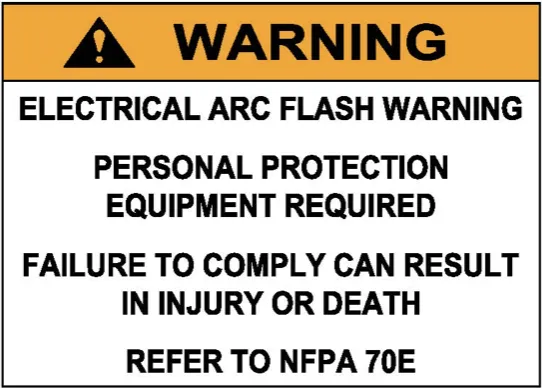

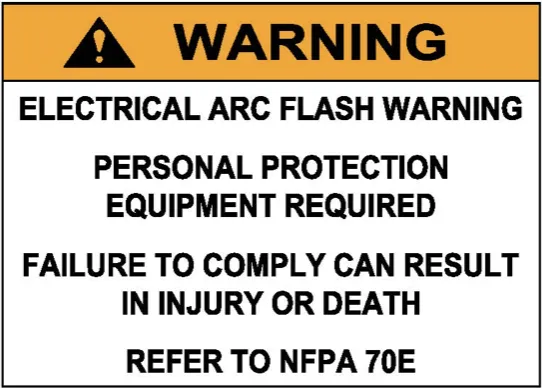

What are Arc Flash Labels?

What Are Arc Flash Labels? These are warning labels that are required by OSHA to be placed on any equipment that requires maintenance while energized. This usually includes equipment like Switchboards, Panels, and Motor Control Centers. Equipment that has no safe method of cover removal like Transformers do not require labels. Also Equipment That is easily de-energized like Disconnects, Starters and VFDs do not require labels as they should not be worked on while energized

There are 2 types of arc flash labels, 𝗯𝗮𝘀𝗶𝗰 labels and 𝗰𝗼𝗺𝗽𝗿𝗲𝗵𝗲𝗻𝘀𝗶𝘃𝗲 labels. 𝗕𝗮𝘀𝗶𝗰 labels are only for 208 Volt panels. These labels have a warning information but no information about energy, PPE, or boundary information. For basic labels you should use the picture in this post and and the provided tables in NFPA 70E to determine proper PPE. 𝗖𝗼𝗺𝗽𝗿𝗲𝗵𝗲𝗻𝘀𝗶𝘃𝗲 labels are for 480 Volt panels. These labels have Shock Hazard Boundaries, Limited Approach, and Restricted Approach distances detailed on the bottom of the label. They also have Flash Hazard Boundary, Energy Levels, and PPE Requirements detailed.

NFPA 70E Requirements

According to the National Fire Protection Association (NFPA) Standard 70E, arc flash studies must be reviewed at least every five years.

This review should account for any changes to the electrical distribution system or to the IEEE 1584 standard.

An arc flash study should also be reviewed any time modifications are made to the facility that can affect the outcome of the study.

Major or minor variations such as fuse type or breaker setting adjustments can have a huge impact on personal safety.

Other times when an arc flash study is required include:

Major additions or modifications to your facilityEquipment is greater than 50 voltsYour state adopted the 2017 edition of NFPA 70You can't de-energize equipment remotely

OSHA requires employers to perform an arc flash hazard analysis and to implement appropriate protective measures, such as the use of personal protective equipment (PPE) and the proper maintenance of electrical equipment.

Arc Flash Study Requirements

Electrical System Diagrams: Gather detailed diagrams and drawings of your electrical system, showing the components, connections, and ratings. This is like having a map of your electrical setup.

Equipment Information: Collect data on all electrical equipment, including transformers, circuit breakers, switches, and panels. You need to know their specifications and conditions, like their age and maintenance history.

Fault Current Analysis: Calculate the maximum amount of electrical current that can flow during a fault (like a short circuit). This helps determine the potential danger of an arc flash.

Protective Devices: Identify and evaluate the protective devices in your system, such as fuses and circuit breakers. These are like safety switches that can prevent or mitigate arc flash incidents.

Clearing Time: Determine how long it takes for protective devices to respond and interrupt the fault current. This is crucial for assessing the duration of the arc flash event.

Working Distance: Define the distance between a worker and the electrical equipment during normal operation. This affects the level of protection needed for workers.

Equipment Labeling: Properly label equipment to indicate potential arc flash hazards. Workers need clear warnings about the dangers associated with specific equipment.

Hazard Categories: Classify the arc flash hazards into different categories based on the potential energy release. This helps workers choose appropriate personal protective equipment (PPE).

PPE Recommendations: Based on the hazard categories, recommend suitable personal protective equipment for workers, like arc-rated clothing and face shields.

Documentation: Keep records of the study, including data, calculations, and recommendations. Regularly review and update this information to ensure ongoing safety.

Arc Flash Study Cost

At EAP, we generally quote Around $120/node, but there is obviously a good amount of variance on that number depending the project.

The cost of an arc flash study can range from $3,000 to $100,000, depending on the size of the facility.

The larger the facility, the more expensive the study is likely to be.

Here are some cost ranges for arc flash studies:

Low end:$3,000Small to medium:$7,500 to $15,000High end:$75,000 to $100,00050 buildings:$625,000 to $960,000

Factors that can affect the cost of an arc flash study include:

The size of the facilityThe experience and qualifications of the electrical engineers

Arc flash studies usually take 4 to 6 weeks to complete.

The results of these studies can help employers:

Mitigate or reduce hazardsProvide labels to raise awarenessInform employeesSelect the proper PPE for the task

Arc Flash Labels

What Are Arc Flash Labels:

Arc Flash Labels are warning labels that are required by OSHA and the NEC to be placed on any equipment that requires maintenance while energized. This usually includes equipment like Switchboards, Panels, and Motor Control Centers. Equipment that has no safe method of cover removal like Transformers do not require labels. Also Equipment That is easily de-energized like Disconnects, Starters and VFDs do not require labels as they should not be worked on while energized.

With that said, here are some must know items about arc flash labels to help you have a safer work environment today! 👊

1. Arc Flash Label Requirements

There are 2 types of arc flash labels, basic labels and comprehensive labels. Basic labels are only for 208 Volt panels. These labels have a warning information but no information about energy, PPE, or boundary information. For basic labels you should use the provided tables in NFPA 70E to determine proper PPE. Comprehensive labels are for 480 Volt panels. These labels have Shock Hazard Boundaries, Limited Approach, and Restricted Approach distances detailed on the bottom of the label. They also have Flash Hazard Boundary, Energy Levels, and PPE Requirements detailed. More on What all this means in the next section.

2. How to Read an Arc Flash Label

The image above is a Comprehensive Arc Flash Label, which we learned in the last section is required on Panels above 480 Volts. Now, we'll cover each piece of information in this label and what it means exactly. Lets start from the top.

24in Arc Flash Boundary: this is the distance where arc flash injuries will likely be limited to 2nd degree burns(1.9cal/cm^2). It is prohibited to work within the arc flash boundary (24in) without proper PPE.

PPE: this lists all the required protective equipment needed to be worn when working on or near this label. It is important to note that Arc Rated PPE will not prevent injury, it only reduces arc flash energy to survivable levels. Another important note is that too much PPE can also be dangerous as it is more difficult to work in. Always use the appropriate level of PPE which is listed at the bottom (12 cal/cm^2).

Shock risk and glove class: this tells you the energy level of the panel, and the thickness of insulated gloves required to open the panel.

Approach boundaries: which are listed as 42 in for Limited Approach, and 12 in for Restricted Approach.

Limited Approach: is the distance where shock hazard exists, non-qualified personnel that are not trained electricians are prohibited to approach within 42 inches of the label.

Restricted approach: is the distance at which any work inside of can be considered the same as actual contact with the energized component.

The last section (12cal/cm^2) is the minimum arc rating which was covered in the PPE section. I hope that helps you better understand comprehensive arc flash labels, their importance, and how to read them. if you have any questions related to arc flash labels, please feel free to reach out via our form or give us a call. We are happy to help!

Arc Flash Labels

What Are Arc Flash Labels:

Arc Flash Labels are warning labels that are required by OSHA and the NEC to be placed on any equipment that requires maintenance while energized. This usually includes equipment like Switchboards, Panels, and Motor Control Centers. Equipment that has no safe method of cover removal like Transformers do not require labels. Also Equipment That is easily de-energized like Disconnects, Starters and VFDs do not require labels as they should not be worked on while energized.

With that said, here are some must know items about arc flash labels to help you have a safer work environment today! 👊

1. Arc Flash Label Requirements

There are 2 types of arc flash labels, basic labels and comprehensive labels. Basic labels are only for 208 Volt panels. These labels have a warning information but no information about energy, PPE, or boundary information. For basic labels you should use the provided tables in NFPA 70E to determine proper PPE. Comprehensive labels are for 480 Volt panels. These labels have Shock Hazard Boundaries, Limited Approach, and Restricted Approach distances detailed on the bottom of the label. They also have Flash Hazard Boundary, Energy Levels, and PPE Requirements detailed. More on What all this means in the next section.

2. How to Read an Arc Flash Label

The image above is a Comprehensive Arc Flash Label, which we learned in the last section is required on Panels above 480 Volts. Now, we'll cover each piece of information in this label and what it means exactly. Lets start from the top.

24in Arc Flash Boundary: this is the distance where arc flash injuries will likely be limited to 2nd degree burns(1.9cal/cm^2). It is prohibited to work within the arc flash boundary (24in) without proper PPE.

PPE: this lists all the required protective equipment needed to be worn when working on or near this label. It is important to note that Arc Rated PPE will not prevent injury, it only reduces arc flash energy to survivable levels. Another important note is that too much PPE can also be dangerous as it is more difficult to work in. Always use the appropriate level of PPE which is listed at the bottom (12 cal/cm^2).

Shock risk and glove class: this tells you the energy level of the panel, and the thickness of insulated gloves required to open the panel.

Approach boundaries: which are listed as 42 in for Limited Approach, and 12 in for Restricted Approach.

Limited Approach: is the distance where shock hazard exists, non-qualified personnel that are not trained electricians are prohibited to approach within 42 inches of the label.

Restricted approach: is the distance at which any work inside of can be considered the same as actual contact with the energized component.

The last section (12cal/cm^2) is the minimum arc rating which was covered in the PPE section. I hope that helps you better understand comprehensive arc flash labels, their importance, and how to read them. if you have any questions related to arc flash labels, please feel free to reach out via our form or give us a call. We are happy to help!

As Seen On

As Seen On

Here's What Others Are Saying

"TEXT FROM THE VIDEO."

"TEXT FROM THE VIDEO."

"TEXT FROM THE VIDEO."

"TEXT FROM THE VIDEO."

"TEXT FROM THE VIDEO."

"TEXT FROM THE VIDEO."

Gallery

Aging Roof? New Homeowner? Got Storm Damage?

You Can Trust Stellar Roofing to Get the Job Done Right

☑ Experienced & Proven Track Record

Our professional team has many years of combined experience in residential and commercial roofing system solutions.

☑ Most Competitive Rates

We make sure our prices are as competitive as possible in our market. Our goal is to make this project as cost-effective as possible without loss of quality. All costs are clarified up front.

☑ 5 Star Reviews

With hundreds of satisfied customers, Stellar Roofing has a plethora of verified consumers that will recommend our service.

☑ We Leave Job Sites Squeaky Clean

After we finish any residential job, we understand how important it is to clean up the job site so your business can go back to its normal routine.

☑ Extremely Thorough Estimates

During the estimate process, our trained roof specialists will note any issues with your roof, big or small, and explain how they can be resolved.

☑ Quality Products & Warranties

We use only the highest quality and top-rated materials. We provide a Lifetime Workmanship Warranty on all roofing and siding projects to coincide with the Manufacturer’s Material and Labor warranty.

We Work With Many Types of Roofs

Asphalt Shingle

Metal

Cedar

Slate

Get Your Free Estimate Today

Our team is here to help answer any questions you may have!

EAP

PO Box 33864, Reno NV 89533

Phone: (916) 414-9855

Copyright © 2023 EAP. All rights reserved.